Remote monitoring and intelligent control system for oil, gas and water well production parameters

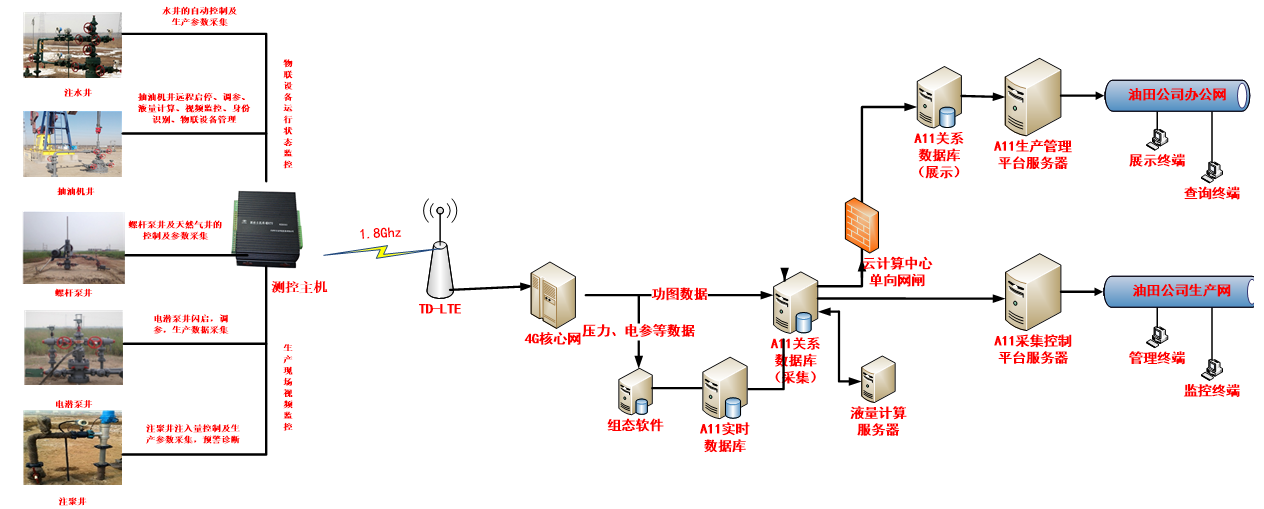

The remote monitoring and intelligent control system for oil, gas, and water well production parameters is the lowest-level, broadest, and most critical on-site component of the oilfield oil and gas production Internet of Things (IoT) project. Its primary function is to collect and control production parameter data from various wellheads, including sucker rod pumps, natural gas wells, self-flowing wells, screw pumps, electric submersible pumps, water injection wells, polymer injection wells, and gas injection wells.

The system comprises three parts: a data acquisition and monitoring subsystem, a data transmission subsystem, and a SCADA central control system. The data acquisition and monitoring subsystem is deployed at the well site, station (plant), and operating area levels to collect data from the production site and implement monitoring functions. The data transmission subsystem is deployed at the well site, station (plant), and operating area levels, using wired and wireless methods for data communication. The SCADA central control system is deployed at the oil and gas field company and headquarters to meet the needs of personnel at all levels for oil and gas production monitoring, analysis, diagnosis, prediction, and early warning.

(1) Collects on-site load diagrams, pressure, electricity, speed, temperature, and flow rate production parameters, achieving automatic data acquisition and wireless remote transmission. It also allows for remote control of the site. Authorized users can remotely set the daily water injection volume for water injection wells, remotely control the water injection volume of individual water injection wells, and remotely adjust the production parameters of sucker rod pump wells;

(2) Analyzes and processes collected field data and calculated results, performing condition diagnosis and using curves, bar charts, pie charts, and tables for analysis, comparison, and display;

(3) Possesses powerful data storage and processing capabilities. It can simultaneously retain all data for each oil and water well, allowing users to generate reports and print load diagrams as needed;

(4) Specific authorized terminal users can perform data entry, modification, and remote control operations. Modification of the primary data collected from on-site meters is prohibited;

(5) Includes a video surveillance system for 24/7 monitoring of oilfield production safety and theft prevention;

(6) Provides audio-visual alarms for sudden changes in production conditions (abnormal load diagrams, shutdowns, power outages, etc.), liquid volume changes reaching a certain set value, abnormal pressure, abnormal temperature, abnormal current, abnormal voltage, significant abnormalities in water injection volume, and shutdowns. Different alarm contents are indicated by different sounds; includes anti-theft alarm functionality for instruments;

(7) Performs condition diagnosis by analyzing changes in production data to diagnose the actual production status of oil, gas, and water wells. It uses neural network-based automatic intelligent analysis to detect broken rods, stuck pumps, insufficient liquid level, sand accumulation and wax deposition, and belt slippage or breakage;

(8) Compatible with various subsystems and can be implemented using GPRS/Zigbee/Wifi/WIA-PA/4G technologies.

Previous Page