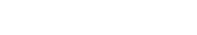

Unattended station and warehouse automation system solution

The unmanned station automation system utilizes computer control, network, and communication technologies to collect operating data and remotely monitor oilfield joint stations, metering stations, water distribution rooms, transfer stations, water injection stations, and gas injection stations. As a crucial component of smart oilfields, it provides fundamental production data for realizing "smart oilfields," accelerating the process of oilfield informationization. The SCADA system of the oil and gas gathering station allows for a comprehensive understanding of the gathering station's production status on the oilfield information network, enabling remote data acquisition and monitoring of the oilfield site, improving oilfield production efficiency, energy conservation, and emission reduction, and enhancing both economic and social benefits.

(1) System Functions

The system platform can collect parameters such as temperature, pressure, flow rate, and water content of incoming and outgoing crude oil, detect parameters such as the liquid level of each tank, oil-water interface level, and high/low alarm status, control the automatic industrial processes of various separators and dehydrators, and realize automatic control of the tank transfer process.

The water system platform can collect the liquid level and temperature of the wastewater pool and buffer tank, as well as high/low limit alarm status, and realize interlocking start/stop control of the pump. It can detect the pressure and flow rate before and after the filter and implement interlocking control. It can also detect the inlet and outlet pressure and flow rate of the water injection pump, provide over-limit alarms, and perform three-phase electrical parameter detection and phase-loss protection for the water injection pump.

The fire protection system platform can detect the liquid level and high/low limit alarm switches of the fire water tank and implement interlocking start/stop control of the fire water pump. It can detect the combustible gas concentration in the incoming oil metering room, outgoing oil metering room, tank transfer pump room, outgoing oil pump room, and tank area, and implement interlocking start/stop control of the fan.

The perimeter security system provides 24-hour real-time monitoring of the perimeter area and computer-aided management, allowing management personnel to understand the actual situation of the surrounding environment in a timely and accurate manner. In case of illegal intrusion, it automatically alarms, displays the alarm area, records the police situation, and automatically forwards alarm information. Equipped with video surveillance, it can observe and record the actual situation of the deployment site in real-time and intuitively, providing reliable data for police situation verification and post-incident processing.

(2) Business Functions

Operation Management Layer: Production process monitoring, early warning information linkage, control command issuance, and production report statistics.

Process Control Layer: On-site production data acquisition, remote control of valve switches, remote control of electricity, fault linkage control, and closed-loop interlocking control.