Contact Us

Market Advisory Services:

Professional and technical services:

Product after-sales service:

Remote data terminal unit (RTU)

Classification:

Key words:

Remote data terminal unit (RTU)

hiddenValue

Product Details

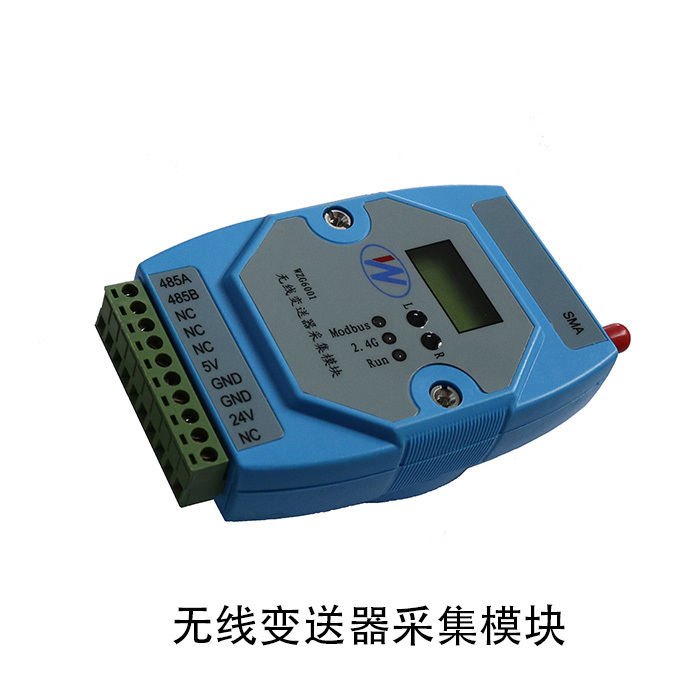

This product uses a modular design, achieving dual redundancy for the CPU, power supply, and network modules. It is equipped with multiple input and output modules for digital and analog signals, including AI, A0, DI, D0, and RS485. All modules support hot-swapping, each signal line has protection, and it uses 4-20mA and RS485 signal lines for highly reliable real-time online monitoring of instruments and control cabinets in small stations and oil and water wells. It also supports wireless communication such as ZigBee/LoRa/4G/WIA-PA.

(1) Supply voltage: DC9-36V;

(2) 32-bit processor, 128M system memory, 256MHz operating frequency, integrated watchdog; 32G large-capacity local storage;

(3) Integrated design, supporting multiple RS232, RS485, AI, A0, DI, DO, RJ45, CAN interfaces;

(4) Supports wireless communication protocols such as ZigBee/LoRa/NB-IOT/4G/5G/WIFI/WIA-PA;

(5) Stable and reliable communication, with automatic recovery function in case of system abnormality;

(6) Supports data transmission protocols such as GPRS/3G/4G/5G/MCWILL; supports IPV4/IPV6 dual-stack protocol, MODBUS RTU protocol;

(7) Supports remote wireless firmware updates and remote parameter settings;

(8) Features watchdog and data power-off protection functions, supports automatic reconnection after power failure, and data transmission;

(9) Low-power design, supports solar power;

(10) Electromagnetic isolation technology, lightning protection design, surge and wave resistance, strong anti-interference capability;

(11) Has local data storage function, data resending, active uploading and self-checking functions;

(12) Real-time data acquisition function; active fault reporting function;

(13) Supports single-unit multi-well and multi-well joint operation modes.

Function Features

(1) Supports low-yield oil well intelligent intermittent operation technology specifications;

(2) Supports motor protection functions: overload protection; short-circuit protection; phase-loss protection;

(3) Stores no less than 20 days of well opening time and historical daily electricity consumption and historical data, and all stored data is not lost after power failure;

(4) Fault diagnosis types: shutdown, rod break, phase loss, no sensor signal, etc.;

(5) Remote and local remote start/stop well and flexible control can be achieved.

Related Products

Product Consulting