Contact Us

Market Advisory Services:

Professional and technical services:

Product after-sales service:

Integrated temperature and pressure transmitter

Classification:

Key words:

Integrated temperature and pressure transmitter

hiddenValue

Product Details

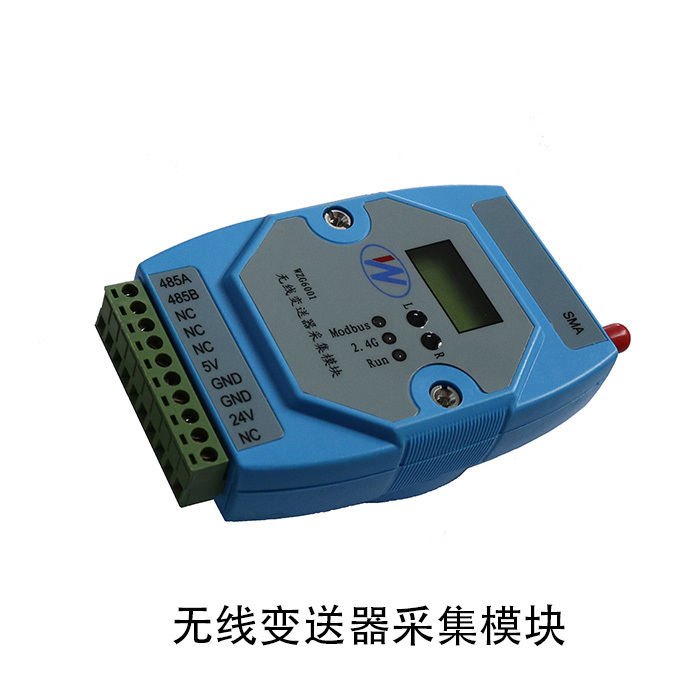

The integrated temperature and pressure transmitter's central sensing unit utilizes globally leading high-precision pressure sensor diaphragm and bellows technology and packaging processes. The pressure sensor diaphragm and bellows are located at the top of the metal body, away from the media contact surface, achieving mechanical and thermal isolation; the glass-sintered integrated sensor leads achieve high-strength electrical insulation from the metal substrate, improving the flexibility of the electronic circuit and its ability to withstand transient voltage protection. The temperature sensing unit uses high-performance, high-reliability imported platinum resistance or thermocouples, and is packaged with a stainless steel metal probe. It uses corrosion-resistant cables with aviation connectors to connect to the display head, facilitating easy plug-and-play disassembly.

This product uses a modular design in its circuit design, with a microprocessor at its core and supplemented by advanced digital isolation technology, giving the instrument extremely high anti-interference and stability. Using the Hart protocol for communication, it can be remotely operated via a Hart handheld device or a computer with Hart software installed to complete the configuration of measurement information. Simultaneously, it uses digital compensation technology and compensates the transmitter through a built-in temperature sensor, improving measurement accuracy, reducing temperature drift, and featuring good long-term stability and high reliability. The user-friendly infrared wireless setting and one-button zeroing function meet the safety operation requirements of hazardous environments, making it very convenient to perform quick menu operations and complete all parameter settings, comprehensively improving the performance of the transmitter.

(1) Measurement Range: Pressure: 0~1MPa~6MPa~10MPa; Temperature: -50~0~150℃

(2) Accuracy Grade: ±0.025%FS、±0.05%FS、±0.075%FS、±0.1%FS、±0.2%FS、±0.5%FS and other accuracy grades (precision grades) are optional;

(3) Uses LCD liquid crystal display; ultra-low temperature can use OLED display screen, supporting normal display of LCD screen below -40℃; with configuration buttons;

(4) Has 4~20mA signal output; multiple communication protocols are optional, supporting HART、MODBUS、FF、PROFIBUS-DP/PA, etc.; with RS485 output;

(5) Has wireless communication function, supporting ZigBee、LoRa、4G、NB-IOT、WIA-PA and other wireless communication protocols;

(6) Pressure diaphragm material: 316/316L stainless steel, gold-plated stainless steel, Hastelloy C-276, titanium, tantalum, zirconium and Monel and other metal materials;

(7) Temperature sensor probe material: 316/316L stainless steel, gold-plated stainless steel, Hastelloy C-276, titanium, tantalum, zirconium and Monel and other metal materials;

(8) Temperature sensor can be adjusted to thermocouple type: K, E, J, T/S type, R type, B type; thermistor type: PT100;

(9) Single channel; corrosion-resistant wiring terminals;

(10) Maximum allowable process temperature: 600℃; Minimum allowable process temperature: -110℃;

(11) Explosion-proof mark: Exdb Ⅱ C T6 Gb;

(12) Protection grade: IP66, IP68 are both satisfied;

(13) The instrument has a self-diagnosis function;

(14) Stability: Differential pressure collection is accurate and reliable, communication is stable and reliable, the system has an automatic recovery function in case of abnormality, and the service life of the differential pressure transmitter itself is not less than 10 years.

Previous Page

Related Products

Product Consulting